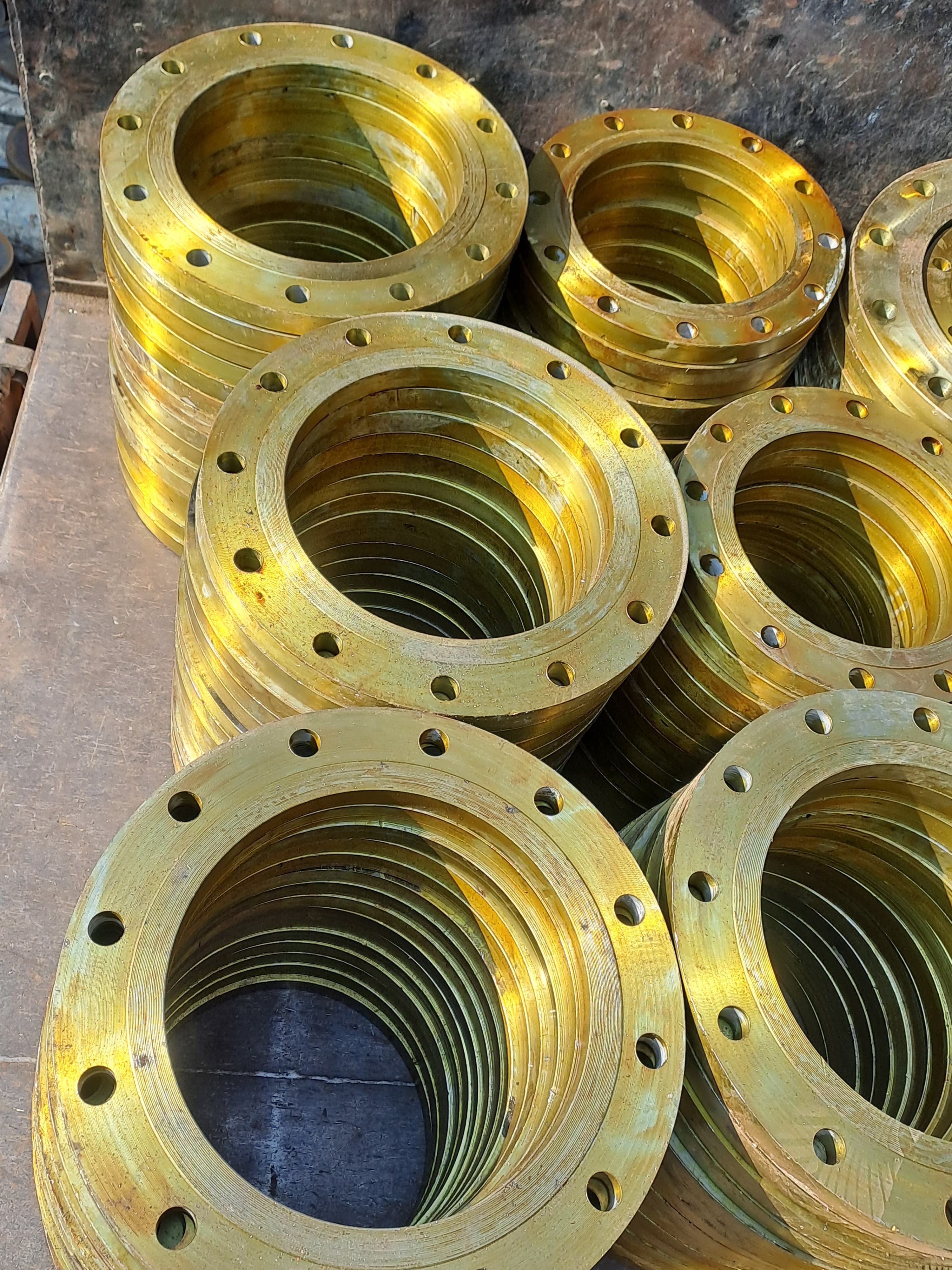

Industrial Flanges

Industrial Flanges Specification

- Feature

- Corrosion Resistance, High Strength, Accurate Dimensions

- Grade

- SS 304, SS 316, SS 316L, ASTM A105, A350 LF2, A182 F11/F22

- Purity

- 99%

- Dimension (L*W*H)

- As per drawing or standard

- Application

- Pipe Fittings, Petroleum, Chemical Industry, Power Plants, Water Treatment, Gas, Engineering Industries

- Product Type

- Industrial Flanges

- Material

- Stainless Steel, Carbon Steel, Alloy Steel

- Standard

- ANSI, DIN, JIS, BS, ASME

- Shape

- Round

- Surface

- Rust Proof, Polished, Smooth Finish

- Connection

- Welded, Screwed/Bolted

- Technics

- Forged, Casting

- Pressure

- 150# to 2500#

- Size

- 1/2 inch to 48 inch

- Color

- Silver

- Tolerance

- ±0.1 mm

- Manufacturing Process

- Hot Forged, Machined

- Rust Resistance

- Yes

- Temperature Range

- -20°C to 600°C

- Hardness

- HB 120-180

- End Connection Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Packing Type

- Wooden Cases, Pallet, Carton

- Weight

- Varies as per size and standard

Industrial Flanges Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 15000 Pieces Per Month

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Loose Packing & Bundle Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2008

About Industrial Flanges

Product Specification :

- Size : 0.5 to 28 Inch

- Thickness : 8 mm To 50mm

- End Used : All Chemical Plant, Boiler, Pipe Fitting, Vahicle Parts

- Product Market : All Over India

- Sample Services : Yes

As one of the distinguished manufacturer and supplier, we are engrossed in offering a qualitative array of Industrial Ms Flanges. The offered flange is widely used in heavy duty piping and fluid passage applications for sealing pipes at their ends. In order to manufacture this flange with high precision, our deft professionals use optimal quality mild steel and progressive techniques. Apart from this, our patrons can easily purchase the provided Industrial MS Flanges at marginal prices from us.

Features:

- Corrosion resistance

- Robust construction

- Excellent durability

- Supreme finish

Precision and Strength in Every Flange

Manufactured using advanced hot forging and machining techniques, these industrial flanges deliver exceptional strength and consistent precision. Their tolerance of 0.1 mm and surface finishing ensure a precise fit, supporting critical applications in demanding environments. Whether used in pipelines, chemical plants, or power stations, these flanges maintain integrity under high pressure and temperature.

Wide Range of End Connections and Standards

Choose from raised face (RF), flat face (FF), and ring type joint (RTJ) end connections, suitable for varied industrial requirements. These flanges are produced to comply with global standards, including ANSI, DIN, JIS, BS, and ASME, and are available in sizes from 1/2 inch up to 48 inches. This flexibility ensures compatibility with diverse piping systems and international projects.

FAQs of Industrial Flanges:

Q: How are these industrial flanges manufactured for optimal performance?

A: These flanges are produced using hot forging and precision machining processes. This method provides excellent mechanical strength, consistent tolerance of 0.1 mm, and ensures each flange meets specified standards for durability, surface finish, and dimensional accuracy.Q: What types of end connections are available for these flanges, and what are their applications?

A: Available end connections include raised face (RF), flat face (FF), and ring type joint (RTJ). RF and FF are often used for general piping and process lines, while RTJ is typically selected for high-pressure, high-temperature, or critical sealing environments.Q: When should a specific grade or standard be chosen for industrial applications?

A: The choice depends on service conditions such as temperature, pressure, and the medium being transported. For corrosive environments, stainless steel grades (SS 304, SS 316/316L) are preferred. For high-pressure or specific industry requirements, selecting the appropriate grade and standard (ANSI, DIN, JIS, etc.) ensures compliance and safety.Q: Where can these flanges be used, and what industries benefit the most?

A: These flanges are widely employed in pipeline systems, petroleum refining, chemical manufacturing, power plants, water treatment facilities, gas handling, and general engineering industries across India and globally.Q: What processes ensure the corrosion and rust resistance of these flanges?

A: A combination of high-purity materials, rust-proof and polished surface finishes, and corrosion-resistant grades (stainless steel, alloy steel) prevents surface degradation, ensuring long service life even in harsh operating environments.Q: How do these flanges contribute to secure and leak-proof pipe connections?

A: Their accurate dimensions, precise machining, correct hardness (HB 120-180), and robust connection options (welded, screwed/bolted) allow for tight sealing and minimal risk of leakage, even under variable pressures and temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Flange Category

Industrial MS Flanges

Minimum Order Quantity : 100 Pieces

Shape : Round

Product Type : Other, Industrial MS Flange

Material : Mild Steel (MS)

Color : Silver, Grey, Black

Mild Steel Flanges

Price 100.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Round

Product Type : Slip On Flanges

Material : MS

Color : YELLOW

Standard Ms Flanges

Price 300 INR / Piece

Minimum Order Quantity : 100 Pieces

Shape : Round

Product Type : Slip On Flanges

Material : MS

Color : YELLOW

Industrial Flanges Manufacturer

Minimum Order Quantity : 50 Pieces

Shape : Round

Product Type : Slip On Flanges

Material : Mild Steel

Color : Standard

Send Inquiry

Send Inquiry